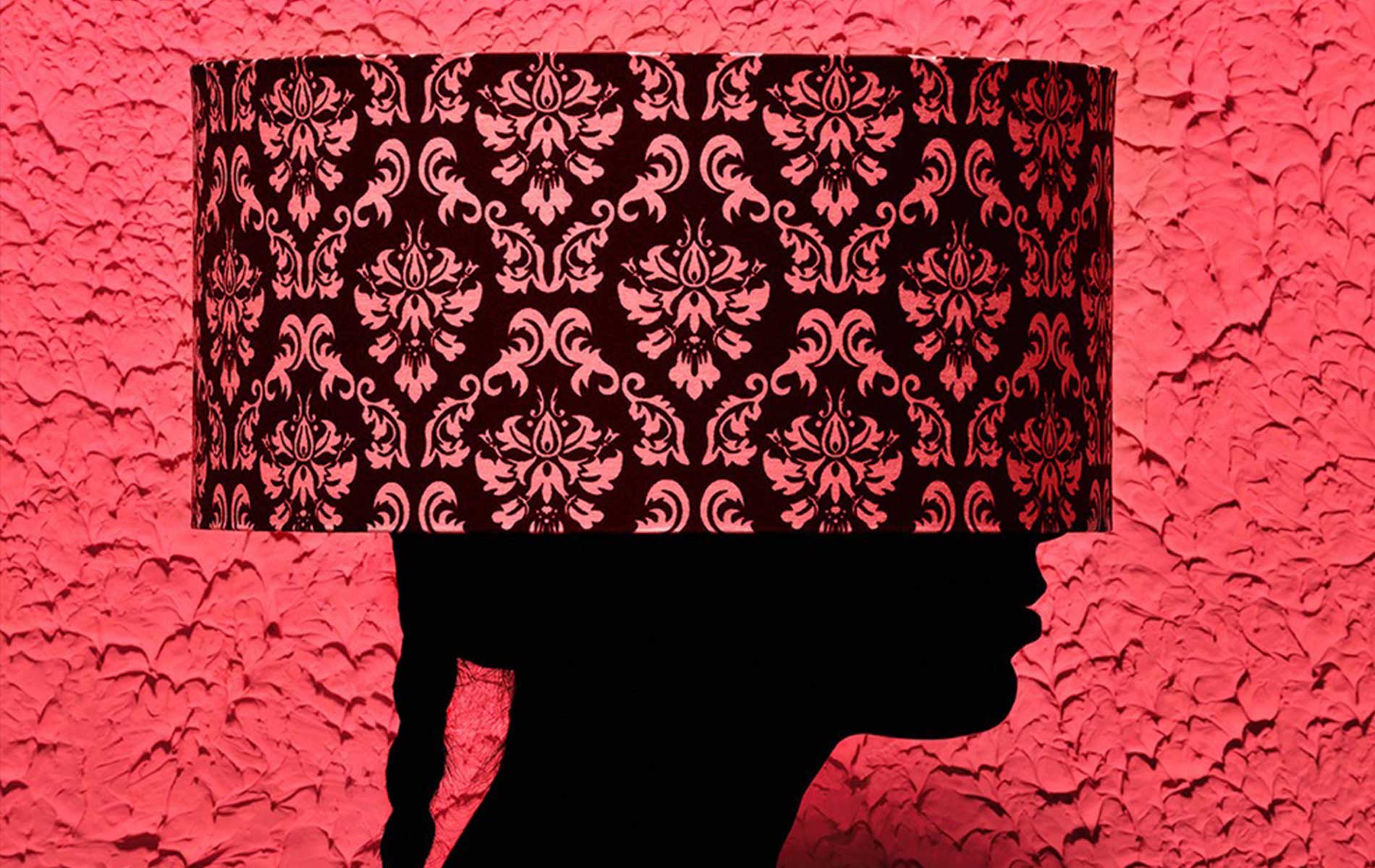

vie-magazine-hero-sarahs-hat-boxes

Now that the Hat Is out of the Box, the Possibilities Are Endless

Sarah’s Hat Boxes

By Laurie Crowley | Photography by David Mendelsohn

It is said that “necessity is the mother of invention.” That statement certainly rings true when talking about Peter and Debbie Mills, owners of Sarah’s Hat Boxes, of Hancock, New Hampshire.

In 1988, Debbie’s mother gave her a kit to make an old-fashioned hat box. The kit didn’t work out properly, but Debbie was intrigued by the process. Through trial and error, and with help from her husband, Peter, she started making hat boxes of her own. On his way home from work, Peter would scour local stores for discarded cardboard and Debbie would shop for bolts of fabric at a discount. They worked tirelessly together to create unique cardboard hat boxes covered in fabric.

Starting out small, they decided to sell their hat boxes at local craft fairs. As new entrepreneurs, Debbie and Peter were excited by the response to their handiwork; they sold all of their boxes at their first fair. But they were also learning some harsh lessons along the way.

Learn from Your Mistakes

“There is always going to be something you don’t anticipate when starting out in business, but that’s how you learn. We would never have developed our sturdier chipboard boxes if it hadn’t rained at a craft fair, causing our boxes to collapse,” remembers Peter. Going home, Debbie and Peter were determined to find a way to make the boxes work.

Another lesson the Mills learned was that it is important to control what you can control. “We made a brochure to showcase our fabric-covered boxes,” Debbie recalls. “We spent all we had on fabric, photography, and print costs. When the orders came in, we realized some of the fabric was discontinued, and we couldn’t fill the orders. We had no control over fabric availability, and that’s when the idea of custom boxes really set in.”

In the early days of their business, Peter would come home from work and then head to Connecticut, Maine, or New York to buy fabric at the big warehouse stores. Meanwhile, Debbie spent her days answering phones, taking orders, creating new designs, making boxes, and, most importantly, taking care of their two children, Sarah and Phil.

“Our name started to get out there after a purchasing agent discovered the many uses for our boxes. He was impressed that he could get them in any quantity, any size, and any fabric, as well as customized screen printing,” says Peter. Sarah’s Hat Boxes can now be found in store displays at Macy’s, Victoria’s Secret, Brooks Brothers, and, more recently, White House|Black Market, as well as other lesser-known but equally important fine stores.

Believe in your Product

Peter recalls the day he received a call from a vendor who was inquiring about his boxes, and was asked whether he would bring some samples to her headquarters in Connecticut. After borrowing twenty dollars from his neighbor for gas, he loaded up the family wagon with garbage bags filled with hat boxes, and headed out. When he pulled up to the address given to him, he was astounded. “Here I am, a machinist at night, making hat boxes in my house by day, and staring at a sign that read ‘Crabtree and Evelyn,’” Peter recalls. “Needless to say, I felt underdressed, ill prepared, and very nervous. But I decided to let the product speak for itself. I left the meeting with our biggest order to date and with a sense of validation and belief in what we were doing.”

Debbie and Peter have some insightful tips for people who have a passion to start their own businesses. They knew their product was good, but realized it would be a challenge to gain the trust and respect of potential clients, given that they were a home-based business. Utilizing what she had, Debbie served tea on the front porch of her quaint New Hampshire home to a client interested in placing a large order. Showcasing the idyllic beauty of fall in New England, while hiding the fact that her kitchen and family room doubled as a factory, was a smart move. The client loved the ambiance, and placed an order. “Always act as if you already have what you are striving for,” says Debbie.

After moving a few times over the years and renting various spaces for their company, Sarah’s Hat Boxes has found the perfect location: Hancock, New Hampshire. With the acquisition of a 15,000-square-foot factory in 2006, Debbie finally has the showroom she envisioned, and Peter has room to expand production.

While Debbie looks at the boxes with an artistic flair, Peter sees the structural component and is always striving to find new ways to create hat boxes that are strong and durable. “We are our own competition,” says Peter. “If you call another company, they will tell you the box size they have available. The difference is that we make the box that the client wants.” Thanks to Peter’s tinkering with a 1922 shearer, which he picked up for $1000, he is able to construct hat boxes from 4 to 24 inches. “I grew up with a skill saw in my hand, and if someone tells me it can’t be done, I find a way to do it,” he says.

The Mills are always looking at ways to update their products. They now offer dye sublimation, a process by which an image on paper can be transferred onto fabric with photo-quality results that will last a lifetime. The Mills also recently purchased the rights to thousands of Norman Rockwell images, allowing them to offer hat boxes adorned with what many would consider good, old-fashioned Americana.

One Simple Rule

Debbie and Peter have watched their business grow by following one simple rule: “Stay true to yourself.” Debbie recalls how she never wasted anything in the early days. “We reused cardboard, ribbon, and fabric out of necessity. We were green before it was in style! We never use toxic materials. That is why we won’t offer leather-covered boxes—toxic adhesive is needed to affix leather, and we don’t want to expose our employees to any harm.”

Because both Debbie and Peter are on the floor working side by side with their employees, there is a sense of camaraderie. “We value our employees,” continues Debbie. “If someone needs to leave at 3 o’clock to catch a high school soccer game, we’re okay with that. Our philosophy is ‘just get the job done.’ Our children are grown, but we understand. We made it a point to attend after-school activities, and we want our employees to do the same.”

Customer service is a top priority.

Debbie remembers that when they were struggling to fill orders, pay bills, and keep the family running, they would always treat their customers as if they were their most important clients. It didn’t matter whether the order was for one or one thousand boxes. “We are here for our clients,” says Debbie.

As the business continues to grow, both Peter and Debbie are amazed at the opportunities presented to them on a daily basis. “Our name is getting out there,” says Debbie. “People respond to quality and customer service, and that is what we’re all about.” Debbie has had designers call her for a hat box needed for an episode of The Young and the Restless. “I’ve recorded the episode, but haven’t had time to watch it yet,” admits Debbie. Havit Advertising Inc. contracted with Sarah’s Hat Boxes to make boxes for AMC’s Emmy Award-winning show, Mad Men. HBO used hat boxes to fill with gifts for their shows, Sex and the City and The Sopranos. Producers for Ugly Betty ordered hat boxes to be used in an upcoming episode, and InStyle magazine features Sarah’s Hat Boxes in their holiday issue for gift packaging ideas. “We try to accommodate our clients; we will even fill the boxes with gifts (or swag, as it’s known), and ship them,” says Peter.

Looking Back

With their Internet sales flourishing and industry-wide recognition, Sarah’s Hat Boxes is a lesson in perseverance and hard work. Debbie and Peter look back on the early days without regret. “How could we appreciate the fact that fabric dealers now come to us if we had never had to drive so many hours to find them? What would have been the motivation to work hard and expand the warehouse if I hadn’t had to clear a path in front of my television on Sunday afternoon just to watch the New England Patriots play?” Peter mused.

When dealing with new vendors, Debbie keeps in mind that she was once in their position. “You have to give people a chance,” she says. “We all need a break when starting out. I try to treat everyone with the same respect I want for myself.”

Moving Forward

The Mills are hoping to inspire others to follow their now-fulfilled dream of starting a business, although they caution that it’s not easy and it’s certainly not guaranteed to be an overnight success. But the rewards far outweigh the drawbacks. Setting your own hours, meeting more people than you ever thought possible, and never knowing what tomorrow holds are just a few of the positives that drive them. “Every day, we do the same thing, but every day is different. Whether the box is for Paul McCartney or Ringo Starr (yes, we made boxes for them), or the bride down the street who wants a custom box to hold her wedding cards, we feel a sense of excitement that someone is getting enjoyment from our hat boxes,” says Debbie.

Now that the hat is out of the box, the possibilities are endless.

For more information about Sarah’s Hat Boxes, please see their ad on the back cover of this magazine, or visit www.sarahshatboxes.com.

— V —

Laurie Crowley lives in Peterborough, New Hampshire, with her husband, Rob, and her four beautiful children.

Share This Story!

KEEP UP WITH THE LATEST STORIES FROM VIE