vie-magazine-ef-san-juan-hero-min

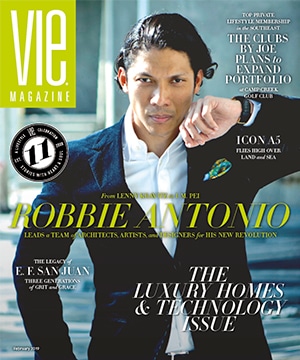

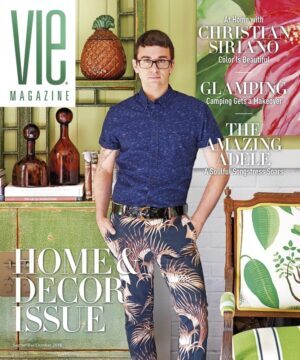

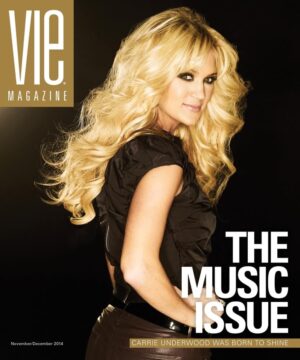

The exterior trim and other custom millwork on this beautiful home in Santa Rosa Beach, Florida, was produced by E. F. San Juan. The firm worked closely with Paul Geary of T.S. Adams Studio Architects and builder John Brown at Gulfview Construction on this project. | Photo by Romona Robbins

A Legacy Continues

From Trial to Triumph

By Tori Phelps

There are a lot of things you might expect someone whose family business was all but destroyed by Hurricane Michael to say. “I wouldn’t change it” isn’t one of them.

When the Category 5 storm blew through the Florida Panhandle last October, it decimated thousands of homes and businesses, including E. F. San Juan, the third-generation custom millwork company where Edward San Juan serves as president. More than a job or even a career, E. F. San Juan is the axis around which Edward’s life revolves. It’s where he and his father took a leap of faith, where his family and friends work, and where his late grandfather labored to construct company buildings. It encompasses both his family’s history and its future.

And yet “I wouldn’t change it.”

Considering the blood, sweat, and tears he and the E. F. San Juan team have poured into restoring the Youngstown, Florida–based company in the last nine months—not to mention the mourning they’ve done over things that can never be restored—the statement is bewildering. It becomes easier to understand, though, as he shares stories of the friends, business associates, and even competitors who showed him that life’s worst often brings out humanity’s best. The storm, as it turns out, wasn’t nearly as powerful as the rainbow that followed.

Living in Florida means contending with hurricanes, but Bay County had largely been spared over the years. So when Hurricane Michael gathered steam, many seasoned locals figured it would turn or weaken significantly before it hit. Edward was among them. Five hours before landfall, however, the predictions worried him enough to pack up his family and evacuate to north Georgia.

It was the first time Edward had left for a hurricane. After all, he had a business to run. Founded by his father, Ed, in the 1970s, E. F. San Juan celebrates a family woodworking tradition handed down from his grandfather, Eddie, a master craftsman. The two older San Juans had launched and then sold a successful furniture company in south Georgia, where Edward was raised, but Ed was far too young to retire. Instead, he embarked on a consulting career focused on boosting profitability for sawmills and furniture companies.

- The exterior trim and other custom millwork on this beautiful home in Santa Rosa Beach, Florida, was produced by E. F. San Juan. The firm worked closely with Paul Geary of T.S. Adams Studio Architects and builder John Brown at Gulfview Construction on this project. | Photo by Romona Robbins

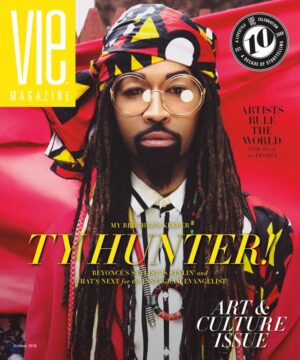

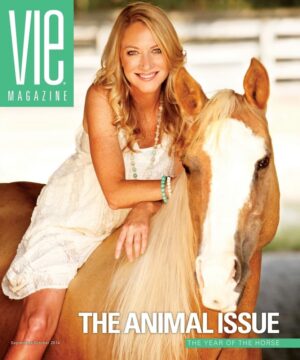

- E. F. San Juan is truly a family business, with multiple generations, in-laws, and family of many team members joining the ranks over the years. Back row, left to right: Bryan Kline, Buddy Czubaj, and Treyson Peirce; Front row, left to right: Eddie San Juan, Mary Kathryn San Juan, Edward F. San Juan, and Edward A. San Juan | Photo by Gerald F. Burwell

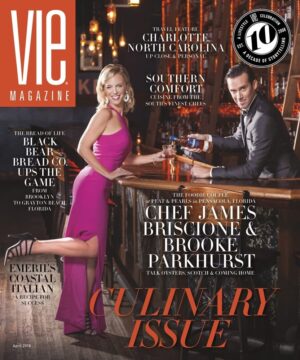

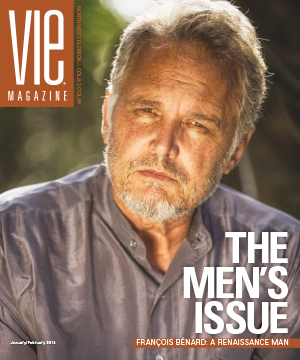

- The team at E. F. San Juan—even those not related by blood or marriage—are family. They all persevered through the devastation of Hurricane Michael and are proud to have the business running again at full capacity a mere eight months later. | Photo by Gerald F. Burwell

He missed the manufacturing part, though, so Ed bought a piece of property and opened E. F. San Juan as a small sawmill in the 1970s. In addition to cutting cypress logs into lumber, he brokered lumber to furniture manufacturing plants and supplied beautifully milled cypress traps to lobster and stone crab fishermen. But that highly niched enterprise evaporated in the 1980s, as the use of cypress for traps became an environmental concern and they were replaced by wire traps. By then, Edward, who had been working at E. F. San Juan every summer for years, was in his final year of graduate school at the University of Florida. His father gave him that year to create a business plan, offering him a partnership in something they would, essentially, start from scratch.

Edward, who says he’s had sawdust in his veins from a young age, knew he was all in. He also knew one other important thing about himself and his father: they had what he calls a “compulsion” for extreme quality. When they milled something, it was perfect. They homed in on the renewed interest in finishings like crown mouldings that was sweeping the country—and the fact that the New Urbanist community of Seaside was being built on Scenic Highway 30-A, practically in E. F. San Juan’s backyard.

Opportunity, meet compulsion for quality.

As E. F. San Juan has expanded into products like interior doors, windows, impact-resistant exterior doors, and cabinetry, father and son have remained intimately involved with every aspect of the company. Edward knows how to operate every machine in the business, and both San Juans could write a doctoral thesis on different wood species. “My dad and I love wood,” Edward laughs. “People see how many hours we put into the business and think we’re slaves to it, but they don’t realize we lucked out. We picked something we love doing.”

At eighty-one, Ed still shows up every day, exuding the kind of energy and work ethic that would exhaust a person one-third his age. (“It’s like having Superman for a role model,” Edward confides.) Far from looking toward retirement, Ed supervised a beta project combining woodworking knowledge and computer mastery to help create a new generation of millworkers. Recognizing that college students today have grown up with computers rather than shop class, E. F. San Juan has taken the skill set of hand woodworking and adapted it to computer-controlled processes, resulting in a precision that surpasses conventional techniques.

It becomes easier to understand, though, as he shares stories of the friends, business associates, and even competitors who showed him that life’s worst often brings out humanity’s best. The storm, as it turns out, wasn’t nearly as powerful as the rainbow that followed.

The company’s custom production hasn’t lost any of the artistry or quality since its hand-hewn days, though, as both are integral pieces of the E. F. San Juan formula. Those elements are found in the San Juans’ depth of knowledge about how different woods function, applying that expertise in helping clients choose the right species for their designs, and then engineering every piece and product to last. They’re working with legacy homes, Edward says, and they make legacy products whose beauty runs far deeper than just surface aesthetics. Instead of nails that will eventually rust, for example, they build with traditional tenon joints and add secondary and even tertiary features to ensure longevity.

This emphasis on excellence is a family tradition embraced by Edward’s wife, Mary Kathryn, who’s been the company’s comptroller for twenty years, and their brother-in-law, Buddy Czubaj, a former Air Force officer who serves as the general manager. It’s also been passed down to the third generation of San Juans. Edward and Mary Kathryn’s oldest child, Eddie, who earned a construction management degree, has worked on the construction floor with his grandfather for two years as a manager trainee. Their daughter, Lydia, graduates from Florida State soon and will work with the sales team in the new cabinet division. The youngest, Mario, just turned thirteen—the age at which generations of San Juan youngsters have started working summers in the family business.

Edward is thrilled that his two oldest children are interested in the business, but even if they weren’t, he would still be surrounded by loved ones. Many of his employees have been with E. F. San Juan for ten or even twenty years, and it’s not unusual for husbands and wives or parents and children to work alongside each other at the facilities. “They’re our family,” he states simply but firmly. “As many hours as my dad and I are here, we see them more than we see our blood family.”

It was these folks that the San Juans couldn’t stop thinking about as they hunkered down in Georgia for five long days. Edward and his father were the first to leave the family’s evacuation site and face the inevitable. The night before, Edward tried to prepare himself emotionally by looking at videos and aerial photographs of the community’s damage, but when he was about fifty miles from home, he realized that no pictures could adequately capture the scene. He called his wife and told her to magnify the horror of the images they’d seen by at least tenfold.

As he pulled onto the E. F. San Juan property for the first time, Edward was struck as much by what wasn’t there—virtually any of their physical facilities—as by what was. Though their own homes and families had been just as devastated, about a dozen of his employees were already on-site working to cover machines and protect what little was left from further damage. At that point, Edward and his father didn’t break down over what had been lost; they simply got to work.

Assuming a mantle of leadership was what employees needed from them, and it occurred to the duo that it was what the community needed too. Millions of people pass their location on the way into Panama City, and Edward says he felt an obligation to show that E. F. San Juan wasn’t quitting. Instead, they would be part of a rebuilding movement.

It was a decision that had been made already anyway. During a family meeting while they were evacuated, every option—including one that involved closing the doors forever—was on the table. “It wasn’t something anyone felt good about,” Edward recalls. “When we voted on it, it got zero votes.”

Others voted “no” on that option as well. In the days following the hurricane, the family was inundated with encouragement from friends, customers, and even strangers. Edward points to an email from a colleague turned pal that, even months later, he still can’t read without tearing up. The missive, which he saved under the subject line “Words to remember when the going gets tough,” assured him that everyone in the building industry was behind E. F. San Juan and praised the company’s work ethic, its people, and its contributions to the top-notch construction for which communities along 30-A have become known. It ended with “I’m a customer of yours for life. If you need anything, don’t hesitate to ask.”

That offer, and the many like it, served as a balm for their many wounds and left no doubt in the San Juans’ minds that they mattered to the community and the industry. Words were soon followed by actions, as builder friends took employees off their own job sites to help the San Juan team get its facilities in order. A volunteer group of seventy-five people brought heavy machinery to clear the entire factory. A local nonprofit, Food For Thought, fed E. F. San Juan employees and the volunteer crews. Even competitors reached out, offering their warehouses as unloading and storage facilities. There were so many offers, in fact, that they couldn’t take advantage of them all.

Less than nine months after Hurricane Michael rocked the business to its core, E. F. San Juan has reclaimed nearly all of the square footage it lost. What the company has undertaken, though, is more of a metamorphosis than a restoration. Thanks to greater efficiency woven into the business and a resilience that’s taken root in stakeholders and employees, Edward predicts that the one-year anniversary of the storm will find them operating—and living—at greater capacity than ever before. “We’ll look back at this thing and see it as a positive stimulus for us versus a catastrophe that ended something good,” he says. “We’ve bonded through adversity as a community and a team, and it’s made us better.”

— V —

Visit EFSanJuan.com to learn more.

Tori Phelps has been a writer and editor for nearly twenty years. A publishing industry veteran and longtime VIE collaborator, Phelps lives with three kids, two cats, and one husband in Charleston, South Carolina.

Share This Story!

KEEP UP WITH THE LATEST STORIES FROM VIE